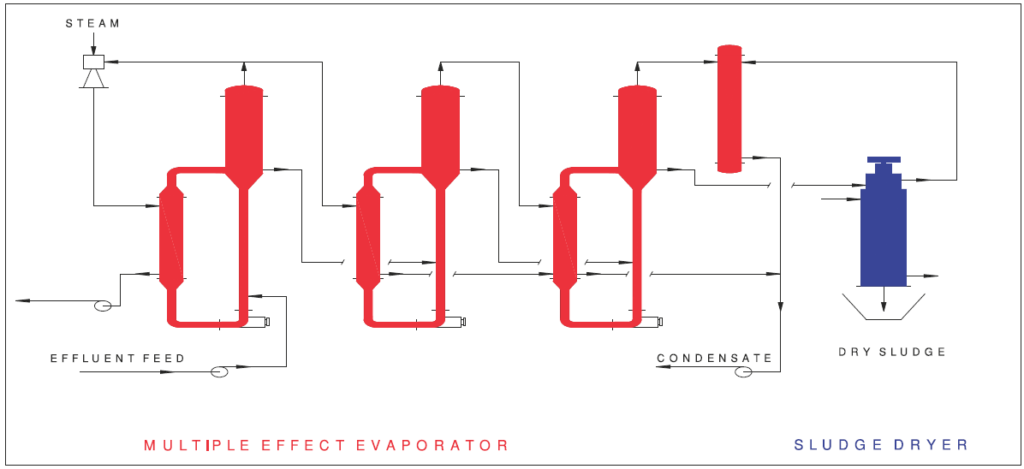

The Multiple Effect Evaporator (MEE) / Zero Liquid Discharge (ZLD) is an apparatus for efficiently using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

Originally designed for concentrating sugar in sugar cane juice, it has since become widely used in all industrial applications where large volumes of water must be evaporated in chemical industries & effluent treatment plants.

Multiple effect evaporation commonly uses sensible heat in the condensate to preheat liquor to be flashed. In practice the design liquid flow paths can be somewhat complicated in order to extract the most recoverable heat and to obtain the highest evaporation rates from the equipment.

Features

- Use of MEE and ATFD reduces operating and disposal cost.

Use of forced circulation evaporator minimize scaling in evaporator. - Indirectly heated dryer gives no dusting,smell or air pollution as in case of direct contact dryer like spray orflash dryer.

- Complete skid mounted system can be offered.

- Fully automatic operation is achieved by PLC based SCADA system.

1st Stage ( Stripper) : Stripper isolates volatile organics from feed to reduce COD.

2nd stage (MEE) : MEE concentrate feed up to flowable slurry level bywater evaporation under vacuum.

3rd stage (ATFD) : ATFD does final drying of MEE concentrate to get dry solids which can be land filled.

Multiple effect evaporator will be falling film or forced circulation evaporators in series with or without thermo compressor to get steam economy. No.of effects will be optimized based on total evaporation load and cost of steam & power at site.