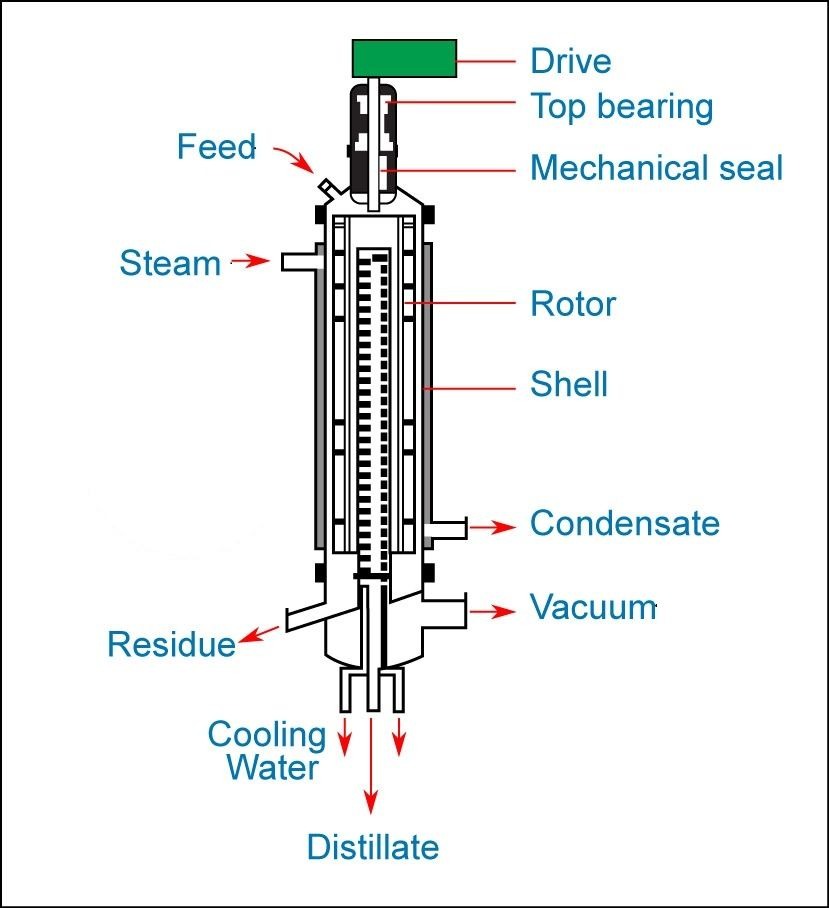

The Wiped Film Evaporator (WFE) is used for concentration, distilling, stripping, dehydration

The operation process in the WFE is simple but yet effective. Feed is introduced at the top of the unit and spread on the shell inner surface by the rotating distribution plate. Specially designed wipers wipe the feed thus creating and renewing the film. This thin film enables an efficient heat transfer even for highly viscous fluids. The low boiling component evaporates and passes through an entrainment separator. This minimizes the carry over of liquid droplets along with the vapors. The vapors are removed through the vapor line to an external condenser (optional) and condensed. For specific applications which demand low pressure drop, the central section of the evaporator is provided with a condenser, thus making the unit a short path/molecular distillation unit. In this case, the vapors are allowed to condense on the outside of the tube bundle and flow out of the

Features

• Low rotational speed

• No bottom bearing

• Higher power to take care of feed fluctuations

• Chevron rotor with interchangeable panels for ease of cleaning

• Conical bottom with auger

• Large internal condenser

• Swing / Hinge wiper blades

Applications

• Evaporation at low operating temperature

• Short residence time (few seconds)

• High heat transfer coefficients

• Low pressure drop on vapor side

• Suitable for viscous liquids

• Continuous operation

• Low maintenance

• No degradation or loss of active ingredients

• Self cleaning\wiping of the heat transfer surface