Lab & Pilot Model

Send your Enquiry

Fill in your requirements here >

Lab SPDU Set up

We are manufacturing Lab SPDU set up consist of SPDU, cold trap, feeding arrangement & glass receivers for distillate & concentrate.

Features of Lab SPDU Set up

- Suitable for feed rate of 1-2 lit/hr

- Heating by thermic fluid or steam up to 300 °C

- Achievable pressure down to 0.001 mbar

- Very low residence time

- Required distillation achieved in single pass

- Suitable heat sensitive product

Pilot plant SPDU

We are manufacturing pilot plant SPDU- With intentation to generate scalable data and results during the pilot tests (with small sample quantities) to enable a later scale up to industrial systems for applications.

Pilot unit is skid mounted unit, consist of feeding arrangement, pre-heater, degasser, cold trap & receivers for distillate & concentrate.

To build the confidence before taking commercial decision of huge investment, mobile lab/pilot plant set-ups available on rent basis.

Features of Pilot plant SPDU

- Along with degasser

- Suitable for feed rate of 10-20 lit/hr

- Heating by thermic fluid & steam up to 400 °C

- Achievable pressure down to 0.001 mbar

- Very low residence time

- Required distillation achieved in single pass

- Suitable heat sensitive product

- Completely jacketed (trace-heated) systems

Lab ATFD / Pilot plant ATFD

We are manufacturing Lab ATFD / Pilot plant ATFD- Feed in form of slurry (range from 30 to 50 % w/w) or solution is converted into thin film which is agitated by rotor on top of dryer. Depending upon the nature of feed we get dry powder at bottom of dryer. Lab & Pilot unit is skid mounted unit consist of feeding arrangement, external condenser & receivers for distillate & concentrate.

To build the confidence before taking commercial decision of huge investment, mobile lab/pilot plant set-ups available on rent basis.

Features of Lab ATFD / Pilot plant ATFD

- Lab ATFD Suitable for feed rate of 1-2 lit/hr & Pilot plant ATFD Suitable for feed rate of 10-20 lit/hr

- Heating by hot water or steam up to 200°C

- Achievable pressure down to 1 mbar

- Very low residence time

- Required recovery of solvent can be achieved with external condenser

Well suitable heat sensitive product

Pilot plant ATFE

We are manufacturing Pilot plant ATFE- Feed entered passes through the distributor plate on internally heated wall. Thin film gets agitated by high speed rotor. Vapor generated in this process flows counter-currently & passes through entrainment separator. Pilot unit is skid mounted unit consist of feeding arrangement, pre-heater, flash separator, external condenser & receivers for concentrate & residue.

To build the confidence before taking commercial decision of huge investment, mobile lab/pilot plant set-ups available on rent basis.

Features of Pilot plant ATFE

- Suitable for feed rate of 8-15 lit/hr

- Heating by hot water or steam or thermic fluid up to 400°C

- Achievable pressure down to 1 mbar

- Low residence time eliminate thermal degradation

- No scale formation of heat transfer surfaces

- Suitable for highly viscous solutions

- Well suitable heat sensitive product

Liquid-Liquid Extractor Pilot plant (LLE)

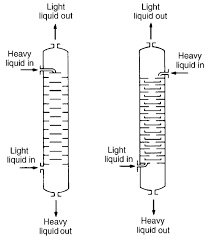

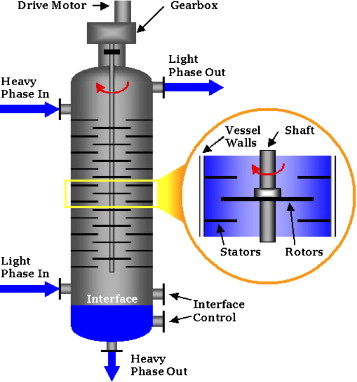

We are manufacturing Liquid-Liquid Extractor Pilot plant (LLE)– It is rotating disc type extraction column. Counter current extraction process take place in LLE. At outlet we get extract enriched with desired product & raffinate with small amount of product. Pilot unit is skid mounted unit consist of feeding arrangement for light phase, heavy phase & settlers.

To build the confidence before taking commercial decision of huge investment, mobile lab/pilot plant set-ups available on rent basis.

Features of Liquid-Liquid Extractor Pilot plant (LLE)

- Suitable for feed rate of 10-20 lit/hr of light phase or heavy phase

- Suitable for continuous extraction

- Improvement in yield

- Reduction in quantity of solvent required

- Less space & less power requirement

Rising film & falling film evaporator Pilot plant

We are manufacturing Rising film & falling film evaporator Set up skid mounted unit of pilot plant consist of separator, condenser & receivers for distillate & concentrate.

Features of our Rising film & falling film

- Suitable for feed rate of 10-20 lit/hr

- Heating by hot water or thermic fluid or steam up to 300 °C

- Can operate under reasonable vacuum

- Low residence time

- Suitable for heat sensitive products