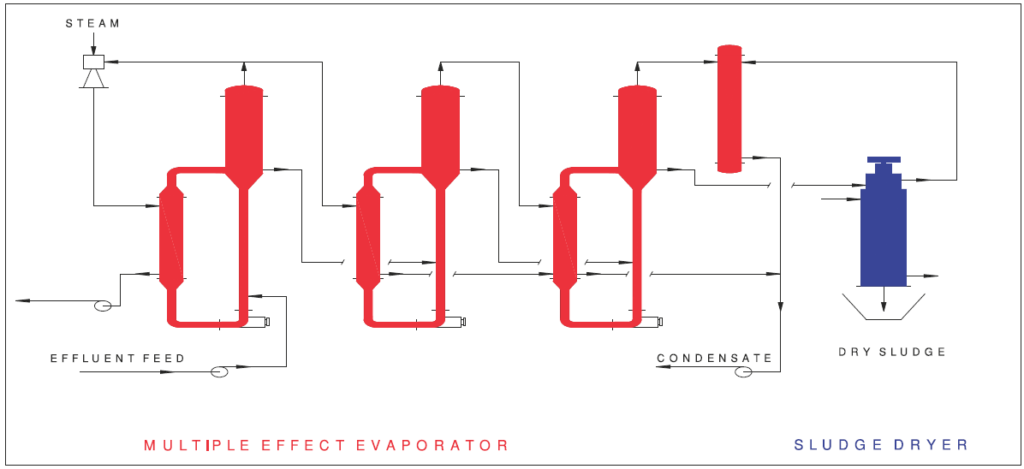

The Multiple Effect Evaporator (MEE) is an apparatus for efficiently using the heat from steam to evaporate water. In a multiple-effect evaporator, water is boiled in a sequence of vessels, each held at a lower pressure than the last. Because the boiling temperature of water decreases as pressure decreases, the vapor boiled off in one vessel can be used to heat the next, and only the first vessel (at the highest pressure) requires an external source of heat. While in theory, evaporators may be built with an arbitrarily large number of stages, evaporators with more than four stages are rarely practical except in systems where the liquor is the desired product such as in chemical recovery systems where up to seven effects are used.

Originally designed for concentrating sugar in sugar cane juice, it has since become widely used in all industrial applications where large volumes of water must be evaporated in chemical industries & effluent treatment plants.

Multiple effect evaporation commonly uses sensible heat in the condensate to preheat liquor to be flashed. In practice the design liquid flow paths can be somewhat complicated in order to extract the most recoverable heat and to obtain the highest evaporation rates from the equipment.

We can supply multiple effect evaporation from two effect to six effect. Our MEE system capacity ranges of up to 600 KLD. We can also supply multiple effect evaporator with Thermo compressor to get good steam economy & reduce the cost.