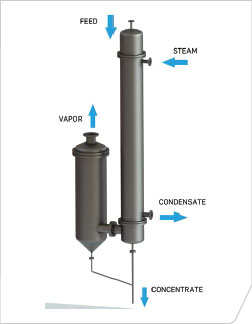

A Falling Film Evaporator (FFE) is a combination of vertical shell and tube heat exchanger and vapor- liquid separator mounted at bottom.

The feed is given at top of shell & tube type heat exchanger having distributor. The liquid falling on distributor get distributed in such a way that it flow down as a thin film on inside surface of the tube. Heat is given on shell side by heating medium. As the feed receives the heat, vapor generated moves at centre of tube co-currently with liquid. The drag of vapor increases the turbulence and improves heat transfer performance. The mixture of liquid and vapor gets separated in vapor-liquid separator at bottom.

Features

- Circulation pump is needed in most cases to maintain proper wetting rate at bottom of tube.

- Small hold up gives quick response to change in operating conditions.

- Gentle evaporation with short residence time.

- Suitable for heat sensitive productions.

- Multiple effect arrangement can be provided to reduce steam consumption.

Applications

- Concentration of dilute solutions of heat sensitive products in water or organic solvent.

- Re-boiler to distillation Column.

- Recovery of solvent from heat sensitive product stream or waste stream.

- Used as a preconcentrator before final thin film evaporator to get complete solvent stripping.

- Dehydration of lubricating oil.

- Low Concentration RO reject Concentration